Twin Skin Roofing and Cladding

Proven track record and cost-effective

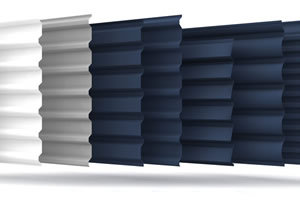

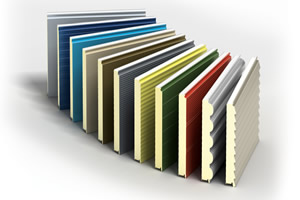

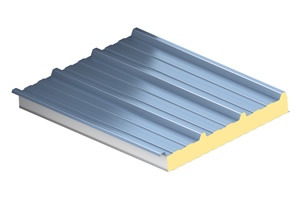

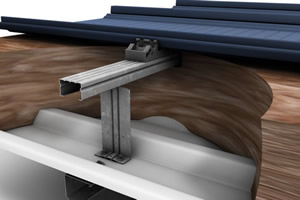

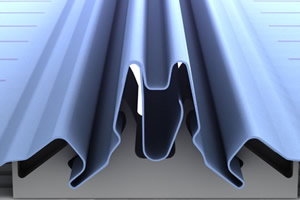

A Twin Skin cladding system comprises of a coated-steel liner sheet fitted to the structural supports and a profiled coated-steel top sheet, held apart by a spacer system. The cavity created in between the two skins is packed with insulation, with its multi-component nature affording the system excellent acoustic properties. A versatile system, it allows many different “U” values to be achieved by altering the depth of the spacer system and incorporating the necessary amount of insulation. A vast range of different external profiles and colours enables architects to express their creativity. The millions of m2 of this system fitted over many decades earns it an enviable and unequalled reputation for reliability, and as the most cost-effective cladding system on the market, it has been the most popular choice within the industry since its inception.